| |

|

![]()

The older LEDs that run at a slightly higher voltage will be fairly close to these measurements giving 5% to 10% lower currents for the same

resistance.

For low power light (night light): Use a 500, 1000 or 2000 ohm resistor in series. The more LEDs you are diving use the lower resistance the

fewer use the high resistance. It is really surprising the amount of light this low amount of power produces especially considering that the batteries

will last approximately 10 times as long.

When wiring in parallel use LEDs from the same batch or same purchase. This helps insure they all run at the same voltage.

Always heat sink the leads between the LED and solder point when soldering. Use an alligator clip between the lead and the LED as a heat sink.

The white LEDs are really sensitive to overheating.

LED lifetime: The red and solid color LEDs can run near 20 ma with about half light output after 100,000 hours. The white LEDs being more heat

sensitive should be designed to run about 10 ma to get the better results. Running at 15 ma in my experience would be the absolute max to be

used for temporary over voltage conditions. The 20 ma max as the manufactures recommend causes rapid degradation in the white LEDs. Always

heat sink the leads of white LEDs when soldering them (especially true for the hotter type soldering irons)

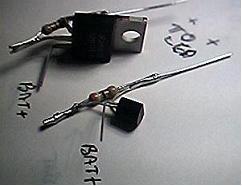

The following shows how to hook up a LM-317 to limit the current flow. The battery source can range from 5 to 35 volts.

This is what it looks like with the resistor in place.

Good technical resource:

http://www.intl-lighttech.com/library/calculators/

http://www.gizmology.net/LEDs.htm

Theoretically a resistor needs to be added to each series combination of LEDs that will be put in parallel with others of like combinations. In

practice this may not be necessary.

You built it. So if one series combination goes out in the ensuing years then you know how to repair it. Either cut the circuit open for the bad series

combination and adjust over all current flow or solder in a new series set. Or replace the bad LED with preferably an LED that came from the

same batch and has been ruining for about the same time frame. In other words repair when you have several series strings of the same types

broken to get one working. Use one series string for spare parts for the others.

The way to tell the ones going bad is to lower the current down below .5 ma for the combination. Any that does not light or are low in light output

or out of balance or are suspect. They could be going bad due to over heating either by soldering or by use.

12 volt lead acid batteries have a usable range of 11.5 volts to 15 volts when vigorously charging. The typical most common range of voltage

encountered under normal use is 12 to 13 volts. Thus the LED should be designed to work between the extreme ranges with focus on the

optimum desired current in the usual range of 12 to 13 volts.

Offered by Mike.